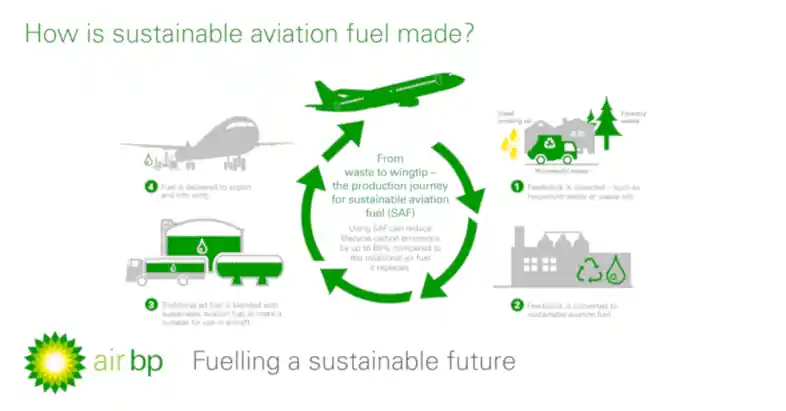

The aviation world is looking for cleaner fuel options. Sustainable Aviation Fuel (SAF) is a big hope. It’s made from renewable sources, not oil, and cuts down on harm to the environment.

The composition of SAF changes based on what it’s made from. It’s not like regular jet fuel. Instead, it comes from things like old cooking oil, plant waste, and algae. Special processes turn these into fuel that planes can use.

SAF works well with planes’ engines. It can mix with regular jet fuel in different amounts. This depends on how it’s made and what it’s made from.

Planes are starting to use SAF. The International Civil Aviation Organization says over 360,000 flights have flown with it. This is at 46 airports, mostly in Europe and the U.S. It’s a big step toward making flying cleaner.

Key Takeaways

- SAF is produced from renewable resources instead of petroleum

- These fuels can reduce aviation carbon emissions significantly

- SAF works in existing aircraft engines without modifications

- Current blending limits range from 10% to 50% with conventional jet fuel

- Over 360,000 commercial flights have already used these sustainable alternatives

- Various feedstocks can serve as raw materials, including waste products

Understanding Sustainable Aviation Fuel (SAF)

Sustainable Aviation Fuel (SAF) is a big help for airplanes. It helps reduce the carbon they make. As more people fly, we need cleaner fuel for planes.

“What is sustainable aviation fuel (…” from www.bp.com and used with no modifications.

Definition and Basic Concept of SAF

SAF is a special biofuel for planes. It can replace regular jet fuel without changing planes or fueling spots. It’s different because it’s made from green stuff like plants and waste.

SAF is made from things like plant oils and waste. It’s processed to be just like regular jet fuel. This makes it safe for planes to use.

SAF is great because it cuts down carbon emissions a lot. It can reduce emissions by up to 80% compared to regular jet fuel. Some SAF even takes more carbon out of the air than it makes.

The Importance of SAF in Modern Aviation

Planes need liquid fuel for now, especially for long trips. This makes SAF very important. It helps planes be cleaner.

Aviation makes a lot of carbon emissions. It’s about 2% of global CO₂ and 12% of transportation emissions. In the US, planes make 9-12% of transportation emissions.

The industry is making big promises. They want to be carbon neutral by 2050. SAF is a key part of this plan.

SAF is a big step towards cleaner flying. It lets airlines fly more without harming the planet. It’s a must for the future of flying.

Next, we’ll look at the different parts of SAF and how they’re made. This will show the good and bad sides of making more SAF.

What is SAF Made Of? The Core Components

Sustainable Aviation Fuel (SAF) is made from biomass and waste. It’s a green alternative to fossil fuel. SAF is made from many renewable sources, not just one like fossil oil.

This makes SAF a great way to cut down on carbon emissions from flying. It keeps flying safe and fast.

The U.S. could grow more biomass to make lots of SAF. The 2023 Billion-Ton Report says we could make 60 billion gallons of clean fuel. This shows SAF could change flying for the better.

Primary Feedstocks Used in SAF Production

SAF is made from many different things. These are the main parts of SAF.

Lipid-based feedstocks are common. They include used cooking oils and animal fats. Vegetable oils like soybean oil are also used.

These oils are full of hydrocarbons, which are needed to make fuel.

Agricultural and forestry waste is another big source. Corn stover and wood waste can be turned into fuel. They need more work but are very useful.

Municipal solid waste is also used. Food scraps and plastics can be turned into jet fuel. This helps solve waste problems.

Algae and microorganisms are new sources. They can make oils quickly and use carbon dioxide. These new sources are good for making more SAF without taking up food land.

Chemical Composition and Comparison to Conventional Jet Fuel

Sustainable Aviation Fuel:

- is very similar to regular jet fuel. It has the same kind of molecules. But SAF has fewer bad stuff like sulfur.

- must meet strict standards for safety and performance. It has to have the right energy, freezing point, and more. This ensures planes can fly well.

- can be used right away without changing planes or fueling systems. It can be mixed with regular fuel up to 50%.

The big difference is SAF is better for the planet. It has lower carbon emissions. This is because it’s made from things that took carbon from the air.

Sustainable Aviation Fuel is a good choice for now. It helps reduce carbon emissions. But, we’re also working on new tech like hydrogen and electric planes for the future.

Renewable Biological Sources for SAF

Renewable biological sources are key for making SAF. They are the base of SAF formulation. This makes flying greener. The aviation world uses these natural materials instead of old jet fuels.

These sources are plentiful and can grow back fast. Unlike old fuels, they don’t take ages to make. This makes flying more sustainable.

Agricultural Residues and Crop Waste

Agricultural waste is a big chance for SAF construction. It includes corn stover and wheat straw. These leftovers are turned into fuel, cutting down on waste and emissions.

Using this waste doesn’t take food away from people. It’s made from what’s left over after crops are harvested. This way, we make fuel without hurting food supplies.

Farmers in America get a new chance to earn money. They can sell the waste to make SAF. This helps them in slow seasons and keeps their fields healthy.

By using these practices, farmers keep their soil good. They also help the environment by storing carbon and improving water quality.

Forestry Residues and Wood Waste

Forestry waste is another great source for SAF material. It includes logging leftovers and sawmill scraps. These are turned into fuel, helping the planet.

These materials are special because they’re full of lignocellulose. This stuff can be turned into fuel in many ways. Gasification and Fischer-Tropsch synthesis work well.

Using forestry waste has many benefits:

- It’s easy to find in many places

- It’s cheap because it’s waste

- It doesn’t take food away

- It helps prevent forest fires

Harvesting these materials is done in a way that doesn’t harm forests. By using these sources, flying becomes more sustainable. It shows the aviation world’s effort to use what would otherwise be wasted.

Waste-to-Fuel Conversion for SAF

Turning waste into fuel shows how the aviation world is changing. Instead of seeing waste as a problem, it’s now a valuable resource. This way, the industry uses waste to make SAF components and cuts down on fossil fuels.

Municipal Solid Waste as SAF Feedstock

Municipal Solid Waste (MSW) is a big chance for making SAF. Every day, tons of trash go to landfills in America.

The organic parts of MSW can be turned into SAF constituents. This happens through gasification and Fischer-Tropsch synthesis. It makes clean jet fuel from different kinds of waste.

Using MSW as fuel helps the environment a lot. It keeps waste out of landfills and cuts down methane. The fuel made is even better for the planet because it captures carbon.

But, sorting and cleaning MSW is still a challenge. New sorting tech is helping make this process better.

Used Cooking Oils and Animal Fats

Used cooking oils (UCO) and animal fats are key in making SAF. They come from restaurants and meat processing. These fats are great for making jet fuel.

The HEFA pathway is used to turn these fats into jet fuel. It breaks down the fats and makes a fuel that meets aviation standards. This fuel was approved in 2011 for up to 50% blends.

| Waste Feedstock | Conversion Process | Carbon Reduction | Commercial Status |

|---|---|---|---|

| Municipal Solid Waste | Gasification + Fischer-Tropsch | Up to 80% | Early commercial |

| Used Cooking Oil | HEFA | Up to 80% | Commercially established |

| Animal Fats | HEFA | 70-80% | Commercially established |

| Food Waste | Anaerobic Digestion + ATJ | Up to 85% | Demonstration phase |

Waste oils and fats are good for the planet. But, there’s only so much of them. Other uses, like renewable diesel, are also competing for them.

More places are collecting UCO to make SAF. This makes waste oils and fats a big part of making aviation greener.

Advanced Feedstocks and Emerging Technologies

New ways to make sustainable aviation fuel are being explored. This includes using biological systems and making synthetic fuels from carbon. These ideas could change how we make SAF material in the future.

Algae and Microorganisms as SAF Sources

Algae are a big deal in SAF makeup. They grow on land that can’t be used for crops. They need very little water and make a lot of oil.

Some algae make oils that are like petroleum. This oil can be turned into jet fuel. In May 2020, it got approval for use in planes, but only up to 10%.

Scientists are also working on bacteria and yeast. They can turn sugars or CO₂ into fuel. These tiny factories could make making SAF construction easier.

But, making algae and microbe SAF big and cheap is hard. Researchers are trying to grow more algae and find better ways to get their oil.

Carbon Capture and Power-to-Liquid Technologies

Power-to-Liquid (PtL) tech is another big idea. It uses captured CO₂ and green hydrogen to make jet fuel. This is very good for the planet.

Using PtL SAF could cut emissions by up to 99%. It’s like recycling carbon instead of letting it go into the air. This makes it very good for the environment.

But, PtL SAF is very expensive. It costs a lot to make and needs a lot of green energy. This makes it hard to use.

Even so, things are getting better. Renewable energy and new tech might make PtL SAF cheaper. Projects in Europe and North America are working to make this SAF formulation real.

SAF Production Pathways and Processes

SAF is made from raw biomass through different ways. Each method uses special chemical steps to make jet fuel. Knowing what SAF is made of means looking at these conversion technologies.

These methods are real and make SAF on a big scale today. They let different places use what they have, making the supply chain stronger. Let’s look at the main ways to make SAF and how they affect the fuel’s quality.

HEFA: Hydroprocessed Esters and Fatty Acids

The HEFA method is the biggest way to make SAF today. It was approved in 2011 for up to 50% blends. It turns oils and fats into jet fuel in a simple chemical change.

It starts with oils like vegetable oils or animal fats. These oils get changed into straight hydrocarbons by adding hydrogen. Then, they become the right shape for jet fuel through more steps.

HEFA is popular because it’s easy and makes good fuel. But, it can’t grow much because of the need for oils.

FT-SPK: Fischer-Tropsch Synthetic Paraffinic Kerosene

The FT-SPK method was first approved in 2009. It can turn almost any carbon material into jet fuel. This makes it very flexible in using SAF ingredients.

It starts with gasifying feedstocks like trash or plant waste. This makes syngas, which is mostly hydrogen and carbon monoxide. Then, it reacts to form liquid hydrocarbons.

This method is very flexible but needs a lot of money and complex plants. It uses old technology but with renewable materials.

ATJ: Alcohol-to-Jet

The ATJ method turns alcohols like ethanol into SAF components. It was approved in 2016 for isobutanol and 2018 for ethanol. It can blend up to 30% with regular jet fuel.

It starts with alcohols from crops or plant waste. These alcohols get changed into olefins, then into longer chains. Finally, they become the right hydrocarbons for jet fuel.

This method is good because it uses existing ethanol plants. This could help it grow faster than other methods.

Other Approved and Emerging Pathways

There are other ways to make SAF, each with its own benefits. They add to the variety of SAF formulation.

One method, HFS-SIP, uses special microbes to make hydrocarbons from sugars. Another, CH, uses hot water to make better jet fuel. Co-processing blends renewable with regular oil in refineries.

All these methods meet strict standards through ASTM. This variety is key for making more SAF worldwide. As the industry grows, these methods will get better and more options will be available.

SAF Certification and Industry Standards

SAF isn’t just about what’s in it. It’s also about meeting strict standards for safety and the environment. Every SAF type must pass tough tests before it can power planes. These tests make sure the fuel works well and is good for the planet.

ASTM Certification Requirements

ASTM International checks if SAF is okay to use. Their D7566 standard is like a guide for the aviation world. It helps make sure alternative fuels are safe and work right.

Before getting the green light, new SAF types go through a lot. This includes:

- Laboratory testing of fuel properties

- Component compatibility assessments

- Engine performance evaluations

- Full-scale flight demonstrations

After passing, SAF is mixed with regular jet fuel. Right now, SAF can’t be more than 50% of the mix. But, scientists are working to make it 100% safe for planes.

Sustainability Criteria and Certification Schemes

ASTM checks if SAF works like regular jet fuel. But, other groups look at how it’s made and its effects on the planet. They check everything from growing the raw materials to using the fuel.

One important thing they look at is carbon intensity scores. This score shows how much greenhouse gas is made during the fuel’s life. Different ways of making SAF can have different scores.

| Certification Scheme | Primary Focus | Geographic Scope | Key Criteria |

|---|---|---|---|

| Roundtable on Sustainable Biomaterials (RSB) | Comprehensive sustainability | Global | GHG reduction, social impacts, biodiversity |

| International Sustainability & Carbon Certification (ISCC) | Supply chain verification | Global | Traceability, GHG reduction, land use |

| California Low Carbon Fuel Standard (LCFS) | Carbon intensity reduction | California, USA | Lifecycle GHG emissions, carbon credits |

| EU Renewable Energy Directive (RED) | Renewable energy targets | European Union | GHG savings, land use change, food security |

These groups help make sure SAF is made right. They prevent bad things like deforestation. This way, flying can still be good for the planet.

Current Applications and Future Outlook

The aviation world is changing fast. SAF is leading the way with its ability to cut down on carbon emissions. Knowing what SAF is made of lets airlines use it safely. This big change helps the industry be kinder to our planet.

Major Airlines and Manufacturers Using SAF

Big names like United Airlines, KLM, and DHL are using SAF components every day. They see SAF as a green way to fly without losing speed or comfort.

The FAA lets airlines mix SAF with regular jet fuel up to 50%. This rule makes sure SAF construction is safe and works well. It helps the industry feel sure about SAF.

In 2023, Gulfstream flew across the ocean on 100% SAF. Virgin Atlantic did the same soon after. These flights show SAF can power planes safely and well.

Scaling Production and Reducing Costs

In 2023, SAF made up only 0.2% of jet fuel used worldwide. We need to make more SAF fast. This means we must grow production and make making SAF easier.

SAF costs more than regular jet fuel, 2-5 times as much. The price changes based on how it’s made. For example, PtL SAF can be up to eight times pricier than HEFA SAF.

To solve these problems, we’re looking at new ways to make SAF. We’re talking about fixing old plants, building new ones, and finding new ways to pay for it. Governments are helping by offering tax breaks and setting rules for using SAF.

As we make more SAF and get better at making it, prices should go down. Using different materials and ways to make SAF will help too. This way, we can make enough what SAF is made of to meet the world’s needs.

Conclusion: The Future of Sustainable Aviation Fuel

The journey into the world of SAF makeup shows a bright future for cleaner skies. We’ve seen how SAF can be made from many things like used cooking oils and even algae. This makes flying more sustainable.

The aviation world is at a big turning point. It aims to be carbon neutral by 2050. SAF is a key player in reaching this goal, keeping flights connected worldwide.

The Sustainable Aviation Fuel Grand Challenge is a big step forward. It brings together government agencies to use more SAF. They want to use 3 billion gallons by 2030 and 35 billion gallons by 2050. This will cut down on harmful emissions by at least 50%.

Even though there are still hurdles, the progress in SAF is impressive. Airlines are starting to use these fuels more. Also, makers are creating new SAF types that are safe and work well.

The variety in SAF is a big plus. It lets the industry adapt and be strong. This flexibility is key as we move to cleaner fuels in the future.

The future of flying is exciting and new. Planes will still link our world. But, they will run on cleaner fuels that help our planet, not hurt it.

FAQ

What exactly is Sustainable Aviation Fuel (SAF)?

What materials is SAF made from?

How does SAF’s composition compare to conventional jet fuel?

Why is SAF important for the aviation industry?

How are used cooking oils converted into jet fuel?

Can garbage really be turned into jet fuel?

What is the Fischer-Tropsch process for making SAF?

How does the Alcohol-to-Jet (ATJ) pathway work?

Can SAF be made from algae?

What are Power-to-Liquid technologies for SAF production?

How is SAF certified for use in aircraft?

What is the current blend limit for SAF in aircraft?

How is the sustainability of SAF measured?

Why does SAF cost more than conventional jet fuel?

What are the main components of SAF?

How much SAF is currently being used in aviation?

What is the SAF production process?

Shred-Tech’s Efficiency in Depackaging: Best Practices for Recycling

Shred-Tech® leads in efficient depackaging for recycling, handling up to 25 tonnes of mixed organics per hour. By preventing microplastics and reducing landfill waste, Shred-Tech® supports the circular economy with sustainable processes, delivering clean organic streams for recyclers and anaerobic digestion systems…

InstaDoodle Review – A Low Cost Whiteboard Sketch Video Software for Info and Promo Videos

Looking for affordable whiteboard animation software? InstaDoodle – Whiteboard Sketch Video Software helps create engaging explainer and promo videos with ease. Try it now

Top 5 Skateboard Wall Mounts: A Comprehensive Review Guide

Finding the right place for your skateboard can be hard. One fact: wall mounts keep boards safe and show them off. This article reviews the top 5 skateboard wall mounts, helping you pick the best one. Read on! Top 5 Skateboard Wall Mounts Quick Recommendation For a quick recommendation, take a look at our brief […]

Why Your Company Needs a Sustainability Roadmap Yesterday!

Why You Need a Sustainability Roadmap for Your Company Right Now! In today’s business environment, sustainability is no longer just a buzzword; it’s a critical component of any successful enterprise. As global pressures mount from stakeholders, consumers, and regulators, companies without a clear sustainability roadmap risk falling behind. This article will explore why your company […]