Shred-Tech® is a global leader in designing and manufacturing industrial shredding and recycling machinery, including mobile shredding trucks and stationary systems for a wide range of materials.

Key Points for – Shred-Tech’s Depackaging

- Shred-Tech’s efficient depackaging technology can handle up to 25 tonnes of mixed organics per hour, all while ensuring exceptional purity in material separation.

- Contemporary depackaging methods prevent the creation of harmful microplastics by using sophisticated screening techniques instead of excessive shredding or crushing.

- Applying correct depackaging best practices can greatly lessen landfill waste and recover valuable recyclable materials and organic content.

- The DRM Depackaging Machine employs sustainable processes that use less water and energy than traditional recycling methods.

- Effective depackaging benefits both the circular economy and anaerobic digestion systems by providing clean organic streams.

The Depackaging Dilemma: The Importance of Efficient Solutions

It may seem simple to separate packaging from organic waste, but inefficient procedures are causing significant harm to our planet. Every day, tons of recyclable materials and valuable organic content that could have been recycled end up in landfills because they cannot be effectively separated from their packaging. This separation issue is one of the most substantial obstacles in today’s waste management and recycling efforts worldwide.

Bad depackaging practices have implications that go beyond squandering resources. The world’s waste is projected to increase by 70% by 2050, placing a burden on the recycling industry to create more efficient systems. Shred-Tech’s cutting-edge depackaging technology responds to this urgent need by offering solutions that optimize resource recovery and minimize environmental harm.

Common recycling techniques frequently have difficulty dealing with mixed waste streams that include both organic materials and a variety of packaging types. When food products expire while still in their containers or consumer packaged goods need to be disposed of, the inability to effectively separate these components results in unnecessary waste. Advanced depackaging technology provides a way to significantly increase recovery rates and promote a more sustainable waste management ecosystem.

How Bad Depackaging Habits Affect the Environment

When packaging and organic waste aren’t correctly separated, it leads to a number of environmental problems. To start with, the valuable organic material that could be composted or processed through anaerobic digestion ends up decomposing in landfills, and this creates methane—a greenhouse gas that’s 25 times more powerful than carbon dioxide. This is a double whammy because it’s not just bad for the environment, but it’s also a waste of a valuable resource.

Moreover, recyclable packaging materials such as plastic, metal, and glass become unrecyclable when they are contaminated with organic waste. This contamination significantly reduces the efficiency of recycling and often makes materials that could have been recycled unusable. The consequence is an increase in the production of virgin materials, higher energy use, and more pollution throughout the manufacturing supply chain.

If the separation process is not up to par, the environmental impact can be severe, including water pollution due to microplastic contamination in compost or digestate. These tiny pieces of plastic can end up in the soil, waterways, and even our food. By using the right depackaging methods, facilities can avoid these extensive environmental effects and recover valuable resources.

The Issue of Microplastics in Conventional Recycling

Conventional depackaging techniques frequently depend on mechanical shredding or grinding to decompose materials. While these methods are efficient at reducing size, they generate a major issue: microplastics. These small plastic particles—measuring less than 5mm—pollute organic outputs and pose grave environmental and health risks when they enter ecosystems.

Microplastics have been found in drinking water, agricultural soil, and oceans all over the world. Their resilience in the environment is especially concerning, as these particles can take hundreds of years to fully break down. Traditional recycling equipment that uses aggressive shredding techniques unintentionally adds to this growing global problem by breaking plastic packaging into tiny pieces that become impossible to fully eliminate.

The issue of contamination isn’t just about the environment, but also about market viability. The end products that come from recycled organics, such as compost or digestate, have to meet increasingly strict quality standards when it comes to plastic content. If the materials are contaminated with microplastics, they lose their value on the market and might even be rejected completely. This undermines the economic viability of recycling operations. The latest depackaging technology addresses this challenge by focusing on separation rather than destruction, which preserves the integrity of both the organic and packaging materials.

Shred-Tech’s Breakthrough Depackaging Technology

Leading the charge in tackling these issues is Shred-Tech’s groundbreaking depackaging solutions, especially the DRM Depackaging Machine. This state-of-the-art system signifies a new way of thinking about the crucial job of separating packaging from organic content. Instead of just depending on destructive processes that result in troublesome microplastics, Shred-Tech has developed a technology that focuses on clean separation while preserving material integrity.

Understanding the Functionality of the DRM Depackaging Machine

The DRM Depackaging Machine is designed to effectively separate materials with the least possible degradation. The machine receives packaged waste through a controlled infeed mechanism to start the process. A combination of mechanical forces, which have been carefully engineered, is used to open the packaging without causing it to excessively fragment. This is an important distinction because the aim is to extract the organic material contained within the packaging rather than grinding everything together.

After the packages have been opened, the system uses an advanced separation method that relies on physical properties such as density, size, and moisture content to differentiate between organic materials and packaging components. This multi-step process guarantees high recovery rates for both organic content and recyclable packaging materials. In contrast to traditional systems that may use too much force, the DRM machine preserves the integrity of the material throughout the process, leading to cleaner output streams.

25 Tonnes Per Hour: Unmatched Processing Capacity

With the ability to process up to 25 tonnes of mixed organics per hour, the DRM Depackaging Machine stands out in the industry for its processing capacity. But it doesn’t sacrifice quality for quantity. Even at maximum capacity, the system continues to separate materials efficiently. This means recycling facilities and waste management operations can process more materials in less time, improving their bottom line.

With this level of capacity, the system can be used in a variety of settings, from mid-sized municipal recycling centers to large industrial operations. This ability to handle large volumes efficiently solves one of the biggest problems in recycling workflows. Facilities that used to have backlogs of materials can now handle continuous streams without sacrificing the quality of the separation or creating troublesome microplastics.

Top-Tier Separation Technology

Shred-Tech’s depackaging method stands out in its ability to consistently achieve high purity rates in separated materials. The technology regularly produces organic outputs with less than 0.5% packaging contamination, exceeding industry standards and regulatory requirements by a wide margin. This degree of purity is essential for downstream processes such as anaerobic digestion and composting, where contaminants can interrupt biological processes and decrease the quality of the final product.

Just as well, the packaging streams that have been separated are kept in high quality for the following recycling. Instead of breaking down materials into fragments that can’t be used, the system keeps larger, more easily recoverable packaging parts. This method greatly raises the market value of the materials that have been recovered and increases the amount of possible recycling applications. The main part of effective recycling is clean separation, and Shred-Tech’s technology provides this with amazing consistency.

Minimal Water and Energy Usage

The environmental benefits of the DRM Depackaging Machine go beyond just the separation process. It also operates using significantly less water and energy than traditional systems. This not only reduces operating costs but also lessens the environmental impact. This efficiency in resource use aligns with sustainability goals and also enhances the economic feasibility of recycling operations.

The system is designed to significantly reduce water consumption, which is a key issue in water scarcity and conservation. Many conventional depackaging methods require a lot of water for separation, resulting in polluted wastewater that needs to be treated further. Shred-Tech’s method greatly reduces the need for water, making it a more sustainable model for facilities in areas where water resources are under increasing stress.

Shred-Tech’s design is energy-efficient, further reducing the carbon footprint of recycling operations. The DRM machine uses optimized mechanical systems and smart power management to consume significantly less electricity per tonne processed than other industry alternatives. This efficiency directly reduces operational costs and minimizes environmental impact over the system’s operational lifespan.

Why Current Depackaging Methods Outperform Old Ones

The shift from old to new depackaging methods is not just a slight upgrade—it’s a complete overhaul of the separation process. Old methods usually used forceful strategies like rough shredding, grinding, or pulverization. Even though these strategies were good at breaking down materials, they also caused many issues, especially in terms of material contamination and microplastic production. For more information on sustainable practices, check out our insights on sustainability in depackaging.

Today’s machines, such as Shred-Tech’s DRM Depackaging Machine, have a more advanced method, concentrating on specific separation rather than random destruction. This difference is critical for preserving the quality of the material and maximizing the value of the recovery. By maintaining the structure of packaging materials instead of breaking them down into tiny particles, today’s systems produce cleaner, more sellable output streams for both organic content and recyclable packaging.

Also, old-fashioned methods usually had a hard time dealing with different types of packaging, doing well with some materials but not so well with others. Today’s depackaging technology can handle a wide range of packaging formats, from plastic films and hard containers to multi-material packaging and even glass. This flexibility lets facilities handle different types of waste without losing efficiency or output quality.

Preventing Microplastic Production

The major benefit of the latest depackaging technology is its capacity to prevent the production of damaging microplastics. Conventional shredding and grinding procedures unavoidably break plastic packaging into minuscule pieces that pollute organic outputs and leak into the environment. These microplastics are an increasing environmental issue, with possible consequences for the entire food chain and ecosystem.

Shred-Tech uses a unique method that focuses on using separation forces to release organic content without significantly breaking down the packaging. The system’s mechanical action is primarily aimed at the packaging’s seams and weak points, rather than shredding everything in sight. This focused approach helps preserve larger pieces of plastic that can be more easily captured and removed during the separation process.

What this means is that the creation of microplastics is drastically reduced. The organic outputs meet, if not exceed, the strictest quality standards for plastic contamination. This is a significant improvement as it tackles the growing regulatory concerns about microplastics. It also enhances the market value and applications for processed organic materials. For facilities that are facing increasingly stringent quality requirements, this is a significant competitive advantage.

State-of-the-Art Screening Techniques for Superior Quality Outputs

In addition to the initial separation process, up-to-date depackaging technology uses advanced screening techniques to further improve output quality. These multi-stage screening systems can identify and eliminate even tiny contaminants that may pass through initial separation stages. The outcome is consistently superior-quality material streams appropriate for high-end applications in both recycling and organic processing.

Modern screening methods use several physical properties such as size, density, moisture content, and optical characteristics to identify and separate contaminants. This multi-parameter approach is much more effective than older screening methods that primarily relied on size separation. By considering several material properties at once, these systems can achieve a level of separation precision that was previously unattainable in industrial-scale operations.

Recycling facilities benefit greatly from these advanced screening capabilities. They lead to higher-value end products and open up new market opportunities. Clean, well-separated materials are highly sought after in recycling markets and can be used for higher-value applications. This economic advantage, along with the benefits of regulatory compliance, makes advanced screening a vital part of today’s depackaging best practices.

Top 5 Advantages of Effective Depackaging Systems

Integrating effective depackaging technology offers a range of benefits that span across recycling operations and more. These advantages make a strong argument for transitioning from conventional separation techniques to sophisticated systems such as the DRM Depackaging Machine from Shred-Tech, a pioneer in inventive recycling solutions.

1. Better Resource Recovery

Current depackaging technology significantly increases resource recovery rates for both organic and packaging materials. While older methods might only recover 60-70% of available organic content, newer systems consistently get recovery rates of over 95%. This substantial improvement means more resource use and less waste.

A standard facility that processes 10,000 tonnes annually can recover an extra 2,500-3,000 tonnes of valuable organic material that would have been discarded as waste. The economic impact is substantial as these recovered materials not only reduce disposal costs but also create new revenue streams through compost, biogas, or other valuable outputs.

Efficient depackaging does more than just help with organics. It also greatly enhances the recovery of packaging materials like plastics, metals, and paper products. Because these systems keep the materials intact during separation, they produce higher-quality recyclables that fetch top dollar on the market.

2. Boosting Revenue with Recyclable Materials

Depackaging is about more than just saving money on operations; it also creates an opportunity to earn more from the materials you recover. When you can cleanly separate materials, you end up with higher-grade recyclables that meet the strict requirements of the market. This allows you to access better prices and a wider range of buyers.

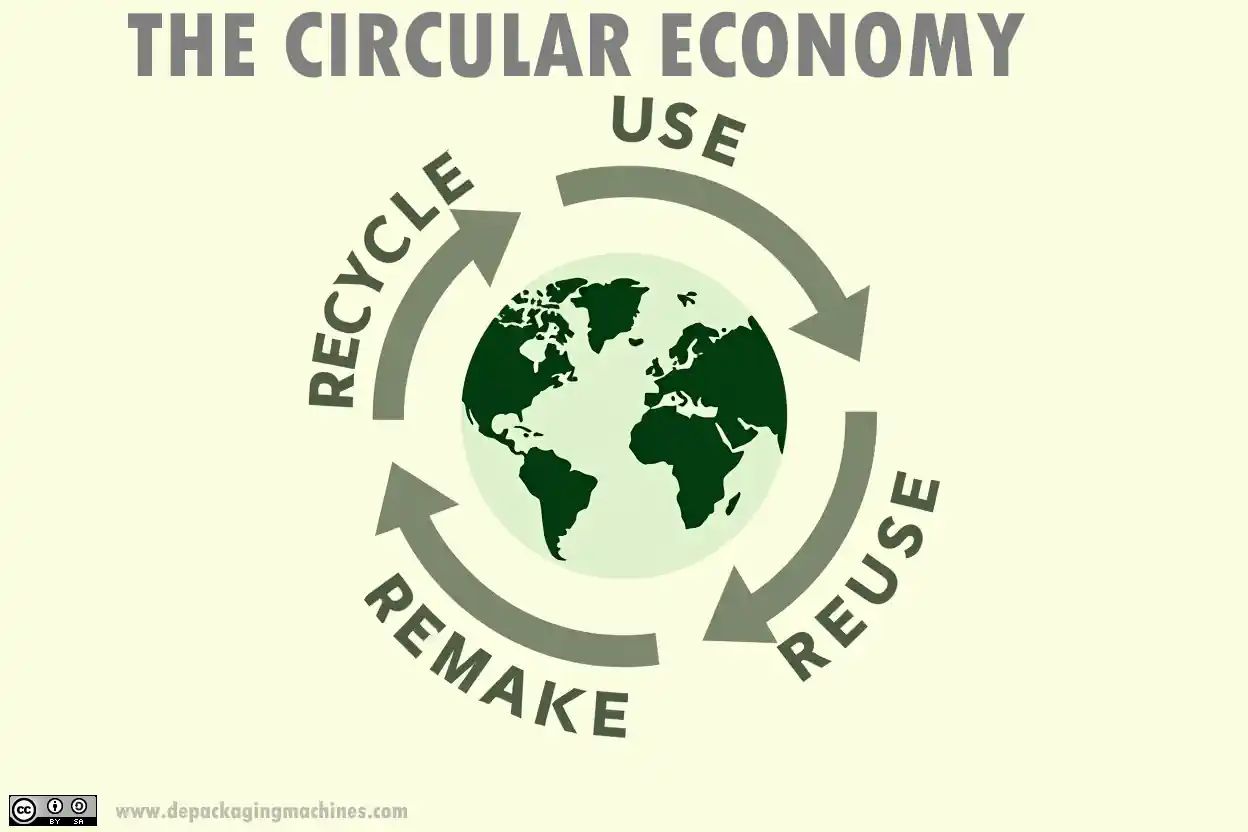

Plastic packaging materials that are sorted using high-tech depackaging systems keep enough quality to be turned into plastic resins. This is a valuable recycling method that is often not achievable with materials processed through traditional methods. These plastic resins are then used as raw materials to create new products. This completes a real circular economy model that brings both environmental and economic benefits.

Just as metals that have been cleanly separated maintain a higher level of purity and value. Even paper-based packaging, which is often damaged in traditional recycling processes, maintains more of its structural integrity and recyclability when processed through systems designed to separate rather than destroy.

3. Major Decrease in Landfill Waste

One of the most noticeable benefits of using efficient depackaging technology is the significant decrease in materials being sent to landfill. These systems are able to effectively separate and recover both organic content and packaging materials, which diverts a large amount of the waste stream from disposal.

With the correct use of advanced depackaging systems, it is possible to achieve landfill diversion rates of over 90%. This is a game-changer for facilities that have previously had to deal with large disposal volumes. The reduction in waste not only benefits the environment, but also leads to significant cost savings as landfill tipping fees continue to increase in most areas.

There are environmental benefits to this beyond just saving landfill space. By keeping organic materials out of landfills, we can greatly reduce emissions of methane, a potent greenhouse gas that has an outsized impact on climate change. This reduction in greenhouse gas emissions is a key environmental benefit that fits in with larger sustainability goals and regulatory requirements.

4. Reducing Environmental Impact

Efficient depackaging technology helps decrease the environmental impact in several ways. The systems use less energy and water than traditional methods, which helps conserve resources during the separation process.

These systems help avoid the creation of microplastics, which are a significant source of environmental pollution that can last for hundreds of years in soil and water ecosystems. This decrease in pollution offers a significant environmental benefit that goes well beyond the immediate operational advantages.

Shred-Tech’s depackaging practices, which are based on the circular economy approach, have a significant impact on the environment by reducing the need for virgin materials. Each tonne of plastic, metal, or paper that is recovered and recycled represents significant savings in energy, water, and raw materials compared to producing these materials from scratch. This resource efficiency translates directly to reduced carbon emissions and environmental impact throughout the supply chain.

5. Assistance for Anaerobic Digestion and Composting

Organics separated cleanly from packaging create the perfect feedstock for biological processing systems such as anaerobic digestion and composting. These downstream processes require consistent, uncontaminated organic inputs to work efficiently and yield high-quality outputs. Learn more about the depackaging process to ensure optimal feedstock preparation.

Organic materials that have been properly depackaged are particularly beneficial for anaerobic digestion facilities. These facilities turn organic waste into biogas, a renewable energy source, and create a nutrient-rich digestate that can be used in place of synthetic fertilizers in agriculture. However, contamination from packaging fragments, particularly plastics, can interfere with the digestion process and negatively affect the quality of both the biogas and the digestate.

Composting operations also need clean organic inputs to produce compost products that can be sold. The latest depackaging technology makes sure that organic outputs meet the highest quality standards, which supports valuable uses in agriculture, landscaping, and retail markets. This quality control has become more and more important as the rules about plastic contamination in compost become stricter all over the world.

How to Get the Most Out of Your Depackaging System

Getting the best performance from your depackaging system is about more than just having the latest technology. By using a range of best practices throughout the whole process, you can increase efficiency, improve the quality of the output, and get the most for your money. These best practices cover everything from preparing the material to maintaining the system and handling the output.

Preparing Your Waste Stream Correctly

The quality of the materials you start with can greatly affect how well the depackaging process works. If you set up good protocols for preparing your waste stream, you can get consistent, predictable results even when you’re working with a variety of materials. Start by doing some basic sorting to remove items that are too big or materials that aren’t compatible. They could damage the equipment or contaminate what you get out of the process.

If your facility processes various waste streams, it’s worth trying to separate materials by type. This way, you can tailor the processing parameters to each type of material, which will improve separation efficiency. Even simple separation, like keeping heavily contaminated materials away from cleaner streams, can significantly improve the overall performance of your system.

Develop and communicate a well-defined set of acceptance criteria for incoming materials to suppliers and collection teams. Consistency in the quality of input materials leads to better output quality and overall system efficiency. Regular checks and feedback mechanisms ensure that these standards are maintained over time, creating a cycle of continuous improvement that ultimately enhances the overall performance.

Best Machine Settings for Various Packaging Types

Today’s depackaging systems have adjustable settings that can be tailored to different packaging materials and formats. You can make the most of this versatility by creating distinct processing profiles for the most common material types that your operation deals with. Rigid plastic containers, flexible packaging, paperboard, and multi-material packaging may all necessitate different processing parameters for the best separation.

Consider adjusting several key variables such as processing speed, separation force, screening parameters, and moisture levels. Make sure to record the optimal settings for each material category and use a systematic approach when changing configurations between different material types. This organized approach ensures consistent results and reduces downtime between processing runs.

Continually adjust these settings based on data collection and analysis. Today’s systems often come with monitoring capabilities that can track performance metrics across different material types and processing parameters. This data can be used to optimize efficiency and output quality across a wide range of waste streams.

Keeping Up with Maintenance for Optimal Performance

One of the most crucial, yet frequently ignored, elements of efficient depackaging operations is preventive maintenance. It’s important to create and follow a thorough maintenance schedule that covers all parts of the system, from the intake mechanisms to the separation units and screening systems. Regular maintenance can help avoid expensive downtime and maintain consistent performance and output quality.

Focus on wear parts that come into direct contact with materials, as these usually need more regular checks and replacement. Pay special attention to screen elements, separation paddles, and conveyor systems in your maintenance routines. Using condition monitoring can help spot potential problems before they lead to failures, cutting down on unexpected downtime and emergency repairs.

Training employees on basic maintenance tasks and how to troubleshoot common problems is crucial. This allows operators to quickly address small problems and know when to call for specialized tech support. A well-maintained system not only works better, but it also lasts longer, improving the return on investment and lowering the total cost of ownership.

The Benefits of a Circular Economy

Efficient depackaging technology is crucial for implementing circular economy principles in waste management. These systems effectively separate and preserve both organic and packaging materials, creating clean, distinct material streams that are essential for a true circular economy. This method turns what was once thought of as waste into valuable resources that can be continually recycled through the economy.

Producing Renewable Energy and Soil Amendments

When organic materials are effectively depackaged, they become the perfect feedstock for anaerobic digestion systems, which create renewable energy and beneficial soil amendments. These digesters transform organic waste into biogas, a flexible renewable energy source that can be used to generate electricity, provide heat, or be refined into fuel for transportation. This energy production is a valuable revenue stream that reduces the use of fossil fuels and decreases greenhouse gas emissions. Learn more about energy-efficient depackaging methods that contribute to this process.

The byproduct of this process, known as digestate, is a fantastic source of organic fertilizer. It’s packed with nutrients that promote the health of the soil and the growth of plants. High-quality digestate can take the place of synthetic fertilizers in farming, which decreases the amount of chemicals used and enhances the structure of the soil and carbon sequestration. The use of digestate in farming creates a genuine circular cycle, as it returns nutrients to the soil for the growth of new food crops.

When these organic materials are sourced from clean, uncontaminated sources, both the economic and environmental benefits are magnified. Depackaging technology that reduces plastic contamination guarantees that both the efficiency of biogas production and the quality of digestate meet the highest standards. As regulations governing soil amendments continue to tighten around the world, this quality assurance becomes increasingly important.

Recovering Plastic Resin for New Items

When it comes to packaging, efficient depackaging opens up possibilities for recovering valuable plastics that can be turned into recycled resins. These recycled resins can be used as raw materials for producing new items, decreasing the need for new plastics and keeping these materials in use. The environmental advantages are significant—producing recycled plastic usually requires 80-90% less energy than producing new plastic and eliminates the effects of extraction.

Today’s depackaging systems, which avoid excessive fragmentation, generate plastic outputs that are particularly well-suited for mechanical recycling processes. These larger plastic pieces can be cleaned, sorted by polymer type, and processed into high-quality recycled resins more effectively. As brands and manufacturers continue to commit to incorporating recycled content into their products and packaging, the market value of these materials continues to rise.

Aside from traditional recycling methods, new and improved recycling technologies like chemical recycling and pyrolysis offer more options for plastics recovered through efficient depackaging. These technologies can handle mixed or contaminated plastics that may not be suitable for mechanical recycling, further increasing circular economy opportunities.

Integrating Shred-Tech Solutions into Your Operations

“Shred Trucks, Industrial Shredders …” from shred-tech.com and used with no modifications.

Upgrading to state-of-the-art depackaging systems is a major operational move that necessitates meticulous planning and execution. Shred-Tech offers all-inclusive assistance during this implementation phase, from the first assessment to installation and continuous optimization. This advisory method guarantees that facilities get the most out of their investment and experience minimal disruption during the transition.

Considerations for Space and Infrastructure

Before you begin, it’s important to evaluate your space and infrastructure needs. The DRM Depackaging Machine is flexible and takes up less space than you might expect given its processing power. However, you’ll need to plan ahead to make sure you have the right setup for material flow, utility connections, and integration with your current systems.

Aside from the area that the equipment occupies, facilities must also take into account the space needed for material staging, output handling, and maintenance access. The best layout is one that allows for a logical, efficient flow from the time the material is received, through processing, and up to output handling. Shred-Tech’s implementation team collaborates closely with facilities to come up with personalized layouts that maximize operational efficiency while taking into account the unique constraints of the site.

Essential infrastructure requirements include enough power supply, control systems that use compressed air, and the right foundations that can support the weight of the equipment and the vibrations caused by operation. There might also be a need for water connections, but the requirements are much less than what traditional systems need. Early planning for these elements can help avoid expensive modifications during installation and ensure that everything runs smoothly once the equipment is in place.

Compatibility with Current Recycling Systems

Most depackaging systems do not operate independently—they must fit seamlessly into existing processing equipment and material handling systems. Shred-Tech’s approach to implementation places particular importance on this compatibility, ensuring that the new depackaging technology improves, rather than interrupts, existing workflows.

When integrating, you need to think about how materials will be transferred between systems, how the control systems will communicate, and how to plan capacity so that there are no bottlenecks. Modern depackaging technology often significantly improves separation efficiency, which can increase the potential throughput in downstream processes because the material streams are cleaner and more consistent. This improvement might require changes to the subsequent processing stages so they can handle the improved material flow.

Another crucial aspect to consider is the integration of data systems, especially for facilities that already have monitoring and reporting platforms in place. When correctly integrated with existing systems, modern depackaging equipment can supply beneficial operational data that improves the overall management of the facility. Shred-Tech provides a variety of connectivity options to facilitate smooth data integration, regardless of the architecture of the existing platform.

Employee Training is Key

The success of any technological implementation is largely dependent on the skill and knowledge of the employees who operate the equipment. Thorough training programs are necessary to ensure that operators are not only familiar with the basic functionality of the equipment but are also aware of the best operating practices for optimal efficiency and output quality. Shred-Tech offers structured training modules that include system operation, maintenance requirements, troubleshooting procedures, and safety protocols.

Aside from the mechanical operation, it’s crucial for the team to grasp the significance of quality control and how the operation parameters impact the output traits. This information allows operators to make knowledgeable modifications based on changes in the input material, ensuring consistent quality even when dealing with a variety of waste streams. Regular retraining is beneficial in preserving these abilities while also introducing updates as technology and best practices progress.

Training for managers should cover a wide range of operational aspects such as monitoring performance, scheduling maintenance, and ongoing improvement processes. This high-level knowledge guarantees that the company can take full advantage of the features of cutting-edge depackaging technology while adjusting to evolving operational needs over time.

Efficient Depackaging: Looking Ahead

Depackaging technology is evolving faster than ever, thanks to stricter regulations, a growing demand for high-quality recycled materials, and ongoing technological advancements. Shred-Tech is a leading player in this evolution, continually researching and developing ways to improve separation efficiency, reduce energy consumption, and expand processing capabilities for a wide range of materials. Facilities that implement today’s advanced systems are well-prepared for future developments. They have established partnerships with technology leaders and have scalable implementation frameworks in place.

Common Questions

These questions and answers provide important information and address common concerns about efficient depackaging technology and implementation. This information is useful for facilities considering upgrading their technology or trying to optimize their current depackaging operations.

Shred-Tech’s technical consultation services can answer any other questions specific to your facility’s needs, providing personalized advice based on your operational needs and limitations.

What kinds of packaging can Shred-Tech machinery handle?

Shred-Tech’s depackaging machinery is capable of processing an impressively broad array of packaging types and materials. The system is adept at handling rigid plastic containers such as bottles, jars, and tubs made of various polymers from PET to polypropylene. The machinery also has no problem with flexible packaging, effectively separating films, pouches, and multi-layer packaging from the organic materials they contain. For more information on the depackaging process, visit our detailed guide.

The Shred-Tech system effectively separates a variety of paper-based packaging, including cartons, boxes, and composite containers like tetrapak. The system is also capable of handling more difficult materials, such as aluminum cans, glass containers, and multi-material packaging. The system’s versatility means that facilities do not have to spend a lot of time pre-sorting and can process mixed waste streams with consistent results. For more information on achieving high separation rates, explore our resources.

Shred-Tech’s system is capable of handling a variety of packaging sizes, from small single-serve containers to larger bulk packaging formats. This flexibility is especially useful for facilities that process diverse waste streams from multiple sources, as it eliminates the need for separate processing lines based on packaging type or size. For more insights into the process, explore the depackaging process.

How does depackaging technology help to decrease microplastic pollution?

Traditional depackaging methods usually use harsh shredding or grinding, which inadvertently breaks plastic packaging down into microscopic pieces. These microplastics pollute organic outputs and often get into the environment through compost, digestate, or wastewater streams. Once they’re out there, these particles can last for hundreds of years and can get into the food chain through soil, water, and air pathways.

Shred-Tech’s method is unique because it concentrates on separation instead of destruction. The technology applies controlled mechanical forces to open packages instead of fragmenting them completely, maintaining the structural integrity of plastic materials. This method guarantees that plastics stay in larger pieces that are easier to capture rather than microscopic fragments that pollute organic streams. Learn more about the depackaging process to understand its environmental benefits.

What is the payback period for a Shred-Tech depackaging system?

The payback period for a Shred-Tech depackaging system can vary depending on the size of the facility, the composition of the waste, and the conditions of the local market. However, most operations see a full return on their investment within 2-4 years. This calculation takes into account several factors such as increased material recovery, higher-value outputs, reduced disposal costs, and operational efficiencies. Facilities that process larger volumes or handle particularly valuable waste streams often see even faster returns.

Not only does it provide direct financial returns, but advanced depackaging technology also allows facilities to be better prepared for the increasingly strict regulations regarding contamination and resource recovery. While it’s more challenging to measure this regulatory compliance value, it’s a significant risk mitigation factor that strengthens the overall investment case. Many facilities have found that the compliance requirements alone make the technology investment worthwhile, and the improvements in operational and material value offer extra financial advantages.

Can smaller-scale recycling operations make use of industrial depackaging machines?

Definitely. While these industrial depackaging systems were typically only seen in larger operations, advancements in technology have made these systems more affordable and practical for medium and smaller facilities too. Shred-Tech provides scalable solutions that are created specifically for operations that process between 5,000 and 15,000 tonnes annually, which includes many regional and specialized recycling facilities.

Improved separation efficiency and contamination reduction often disproportionately benefit smaller operations, as these facilities typically face tighter margins and more limited downstream options for contaminated materials. The ability to consistently produce high-quality outputs opens new market opportunities that may have been previously inaccessible due to contamination concerns.

Even the smallest operations can access advanced depackaging technology through collaborative efforts such as shared facilities or processing partnerships. These models enable several smaller waste generators or processors to share equipment costs and gain access to separation capabilities that would be financially impossible individually.

- Local facilities that process between 5,000 and 15,000 tons each year

- Specialized processors that manage specific waste streams

- Cooperative facilities that serve multiple small generators

- On-site processing at food production facilities

- Agricultural operations that manage packaged organic waste

The wide range of ways these models are used shows how flexible and scalable today’s depackaging technology is in different operational contexts and scales.

What is the maintenance requirement for Shred-Tech depackaging machines?

The depackaging systems from Shred-Tech are designed to provide reliable operation with a manageable maintenance schedule. Regular preventive maintenance usually takes between 4 and 8 hours per month. More in-depth maintenance is carried out quarterly and can take between 8 and 16 hours, depending on the volume and type of material being processed. This maintenance schedule ensures the machines are available for operation as much as possible while also maintaining their long-term reliability. The goal is to provide consistent performance without excessive periods of downtime.

Important maintenance tasks include checking and cleaning the screen, checking wear parts, servicing the lubrication system, and checking the control system. The design of the equipment allows easy access to points that need maintenance, which reduces the time needed for service and makes routine tasks easier. Many parts have a modular design, which allows for quick replacement of parts that wear out without needing to take apart a lot of the equipment. For more insights on maintaining efficient depackaging machines, check out this article.

Shred-Tech offers detailed maintenance manuals, training, and support programs. These resources allow facilities to manage regular maintenance in-house, but they can also access expert technical support when necessary. This two-pronged strategy keeps maintenance costs low while maintaining equipment reliability for its entire operational life. Furthermore, preventive maintenance programs can be tailored to unique operating conditions and processing needs to further enhance performance and reliability.

InstaDoodle Review – A Low Cost Whiteboard Sketch Video Software for Info and Promo Videos

Looking for affordable whiteboard animation software? InstaDoodle – Whiteboard Sketch Video Software helps create engaging explainer and promo videos with ease. Try it now

What is SAF Made Of? An Introduction to Sustainable Aviation Fuel

Discover what is saf made of as we explore sustainable aviation fuel composition, including organic waste, crop residues, and other renewable sources powering eco-friendly flights

Top 5 Skateboard Wall Mounts: A Comprehensive Review Guide

Finding the right place for your skateboard can be hard. One fact: wall mounts keep boards safe and show them off. This article reviews the top 5 skateboard wall mounts, helping you pick the best one. Read on! Top 5 Skateboard Wall Mounts Quick Recommendation For a quick recommendation, take a look at our brief […]

Why Your Company Needs a Sustainability Roadmap Yesterday!

Why You Need a Sustainability Roadmap for Your Company Right Now! In today’s business environment, sustainability is no longer just a buzzword; it’s a critical component of any successful enterprise. As global pressures mount from stakeholders, consumers, and regulators, companies without a clear sustainability roadmap risk falling behind. This article will explore why your company […]